Describe your need and fill in your basic contact information. We’ll get back to you in a timely manner to determine if our services are a good fit for you.

Describe your need and fill in your basic contact information. We’ll get back to you in a timely manner to determine if our services are a good fit for you.

Designer Fertilizer Technology is used to develop, manufacture, and commercialize novel dry and liquid fertilizer products for the turf, landscape, and commodity fertilizer industries. The following sections are examples of technologies and products, some of which are currently being marketed in the turf, landscape, and commodity fertilizer industries. Many of these technologies are available to help you develop new products or improve your current product line.

UFF works closely with ANTG Research and Development (an affiliate company) to develop, scale-up, and commercialize new turf, landscape, and commodity fertilizer products and technologies. A number of dry and liquid designer fertilizers used for turf and landscape applications were developed and commercialized through ANTG Research and Development for customized private label products.

UFF and ANTG Research and Development are knowledgeable about fertilizer ingredients and their fundamental, mechanical and physical properties, suitability, and compatibility for processing and formulation criteria for development and commercialization of designer fertilizers and soil conditioners.

Key aspects of Matrixed Technology is granulation, densification, formulation, the how and when of delivering nutrients, and homogeneous properties. Understanding and properly applying our novel technology supports the development of our products and their commercialization.

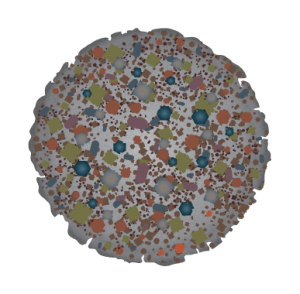

Matrixed Technology is a novel particle-compounding technique to ensure that more nutrients are evenly released into the turf. As demonstrated by the pictures, nutrients are embedded into the granule. Rather than mixing different types of nutrient particles into a single fertilizer granule, ANTG manufactures products so that each particle contains every vital nutrient. Each granule is homogeneous, ensuring a more even and timed-release application of nutrients.

Our matrixed fertilizer releases unreacted urea and available nitrogen during the first 28 days for an initial, quick surge of growth. Turf appears greener and denser. Greening then remains consistent as the water-soluble, controlled-release nitrogen is released during days 21-84. Lastly, hot-water-soluble nitrogen is released during days 70-168. A single application of our matrixed fertilizer provides constant turf nutrition for as many as 168 days.

During our manufacturing process, the nitrogen polymer acts as a binding agent for all other nutrients. Because the phosphorus, potash, and micronutrients are entrapped within the polymer matrix, the potential for burn is reduced and the turf receives a steady, gradual feeding of the total nutrient package. You will see the proof in consistent greening, density, and root growth.

Microscopic View

Products

Bridge Products: Nitrogen Polymer combined with Synthetic and Natural and Organic Nutrients

The key property of this novel technology is the complex formation (Sequestered) of protein and polysaccharides and metals to deliver specific nutrients to the turf and to support soil microbes through liquid/foliar products. Sequestered, also referred to as chelation, nutrients can be readily absorbed by the plant and assist in nutrient up-take. The technology accommodates different formulations and allows for synthetic, natural, and organic nutrients to be used in products, including metals such as iron, manganese, copper, and zinc.

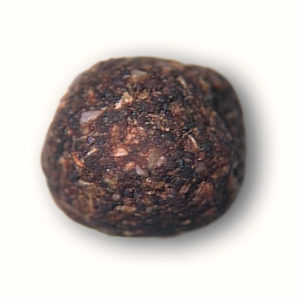

Natural/Organic Technology involves granulation, densification, formulation, and homogeneous properties. Understanding and properly applying this technology supports the development of our products and their commercialization.

Microscopic View

Products

Single Ingredient Specialty Products

Sustainable Agriculture Technology is used to develop, manufacture, and commercialize novel products for the turf, landscape, and commodity fertilizer industries—addressing environmental and nutrient management regulations. UFF and ANTG Research and Development (an affiliate company) has made sustainable agriculture a core theme in its efforts to develop and commercialize fertilizer and soil conditioner products. Many of its current projects are addressing eco-efficiency, relating to energy, water and waste, and life cycle assessments. For example, UFF and ANTG Research and Development are working diligently to develop and commercialize fertilizer and soil conditioning products from concentrated ash, carbon-rich biochar, and wood ash nutrients recovered from renewable energy from thermal conversion of manure and biomass.

There are recovered nutrients from many different industries and processes that readily meet quality and nutrient profiles that make them suitable for agricultural application. The mechanical, physical, and nutrient properties of recovered nutrients can be assessed to determine if they can be recycled.

Our technology and granulation practices will allow these products to compete in fertilizer and soil conditioner markets and high-end turf and landscape markets with chemical fertilizers that originate from mined and synthetic sources.

Wood Ash

Compost

Dried Poultry Sludge

Feather Meal

Fermentation Biomass

Biochar-Poultry Litter

Humus

Sunflower Ash

Ash-Poultry Litter

Blood Meal